Shuimu induction furnace supply for business

1. The creation of Shuimu aluminum melting furnace involves some advanced technologies. They include mechanical systems technology, automatic control technology, sensing technology, and servo-drive technology.

2. The top ranking of Shuimu in induction furnace industry also contributes to the professional customer service.

3. The product features remarkable reliability. It is able to work at low voltage and its advanced circuit has over-loading protection function.

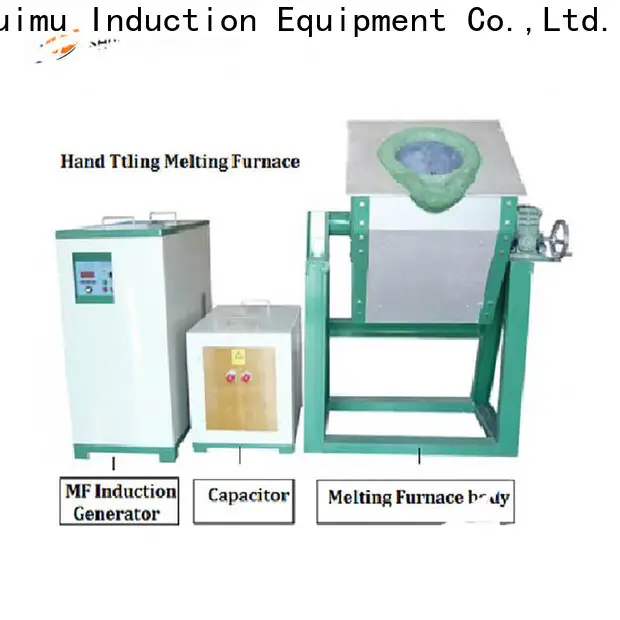

MYF induction melting furnace (middle frequency 1-20KHz) for ferrous and non-ferrous Metal melting. Which covers MF Series ( Manual tilting system) and BF Series ( Electric motor tilting system). SiC crucible for Steel, Iron ferrous Metal melting. Graphite Crucible is for non-ferrous Metal Gold, Silver, Copper, Al, Zinc, Tin, Lead melting. The power size ranges 15-110KW and 1000-1600CM³crucible size.

WF Series melting furnace is designed for Silver, Copper, Al, Zinc, Tin, Lead melting and casting. The power size range 60-300KW and 100-1000kg copper capacity or equivalent.

MF Melting Furnace-Manual Tilting

BF Melting Furnace-Electric Motor Tilting

WF Melting Furnace for Non-ferrous Metal Melting

Company Features

1. Qingdao Shuimu Induction Equipment Co.,Ltd. is a China-based manufacturer of aluminum melting furnace . We specialize in design, production, and sales and is renowned in the industry.

2. Our induction furnace is qualified with brass melting furnace .

3. Quality and service are always seen as key factors in Shuimu's long-term development. Get info!

QUICK LINKS

PRODUCTS

CONTACT US

Tel : 86-532-89980348

Address : No.25-401, U-Valley Industry Park, High-tech Zone, Qingdao, China

SHUIMU INDUCTION

We provide OEM service for induction heating machine, melting furnace and induction coil, supply technical support for heating treatment, Supply training for product operation.